Key Performance Indicators (KPIs) for Advanced Physical Asset Management

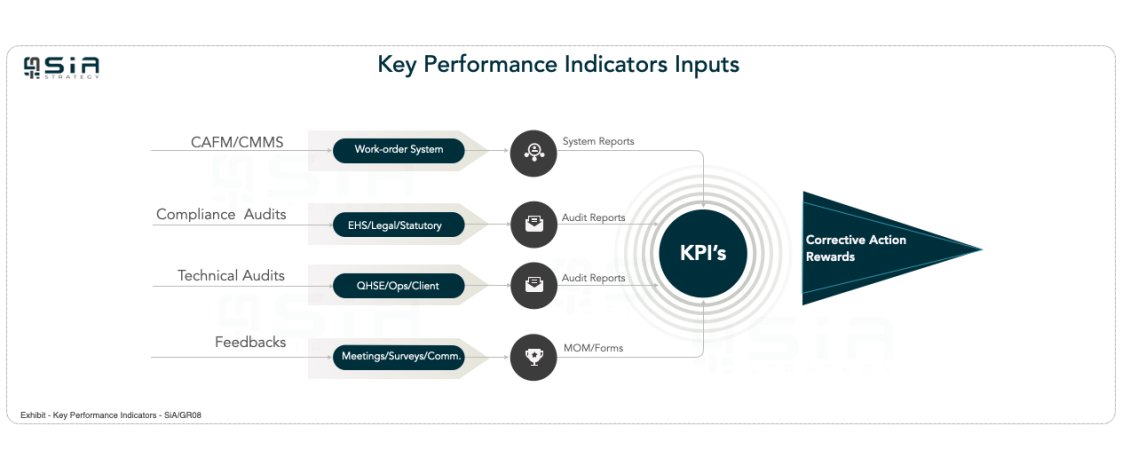

Integrating advanced technology into physical asset management allows organizations to redefine and enhance their KPIs, providing deeper insights and more actionable data. Here, we explore the critical KPIs that are instrumental in driving the success of physical asset management.

Effective physical asset management is about more than just keeping track of equipment and machinery—it’s about optimizing the use, performance, and longevity of these assets to deliver maximum value. With advanced technology, organizations can now achieve real-time visibility into asset conditions, predict and prevent failures, and make data-driven decisions that drive operational excellence. This shift towards a more sophisticated, technology-driven approach to asset management is not just a trend but a fundamental transformation in how businesses operate.

In this comprehensive exploration, we will dive deep into the key performance indicators (KPIs) essential for successful physical asset management in the context of advanced technology integration. We’ll examine how these KPIs can be enhanced and how they contribute to a more efficient, reliable, and cost-effective asset management strategy.

Asset Utilization Rate

- Deep Dive: Asset Utilization Rate is a critical measure of how effectively assets are being used within an organization. Traditionally, this KPI was tracked manually, often leading to inaccuracies and inefficiencies. However, with advanced technologies such as IoT and RFID, organizations can now monitor asset utilization in real-time. Sensors embedded in equipment provide continuous data on how often and how long assets are in use, allowing for precise calculation of the utilization rate.

- Enhancements Through Technology: IoT devices can trigger alerts when assets are underutilized or overworked, enabling managers to redistribute resources more effectively. By analyzing utilization patterns, organizations can optimize asset deployment, reducing idle time and ensuring that assets are used to their full potential.

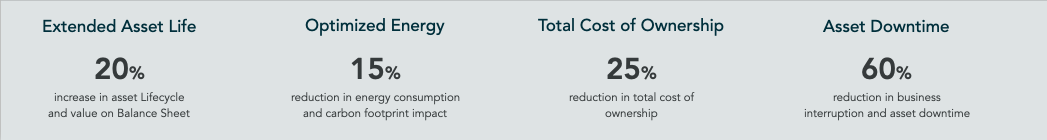

- Impact on Business: High asset utilization rates directly contribute to better ROI, as assets generate more value over their lifespan. Additionally, optimizing asset use reduces the need for additional investments in new equipment, leading to significant cost savings.

Mean Time Between Failures (MTBF)

- Deep Dive: MTBF is a crucial KPI that measures the reliability of assets by calculating the average time between failures. Historically, MTBF was calculated based on past failure records, which often lacked precision. Today, with predictive maintenance technologies, MTBF can be accurately predicted using real-time data from sensors monitoring asset performance.

- Enhancements Through Technology: Predictive analytics tools analyze data such as vibration, temperature, and operational patterns to forecast potential failures before they happen. This proactive approach allows maintenance teams to address issues before they escalate, thereby extending the MTBF.

- Impact on Business: By increasing the MTBF, organizations can significantly reduce downtime, improving overall productivity. Higher MTBF also reduces the frequency and cost of repairs, contributing to lower operational costs and improved asset reliability.

Mean Time to Repair (MTTR)

- Deep Dive: MTTR measures the average time required to repair an asset after a failure. In traditional settings, MTTR could be prolonged due to delays in diagnosing issues or sourcing parts. Advanced technology, such as IoT-enabled diagnostics and automated maintenance management systems, has revolutionized this KPI.

- Enhancements Through Technology: IoT devices can automatically diagnose issues and provide detailed reports on the nature of the problem, significantly reducing the time needed for manual inspections. Additionally, advanced CMMS (Computerized Maintenance Management Systems) can streamline the repair process by managing work orders, tracking parts inventory, and scheduling repairs efficiently.

- Impact on Business: Reducing MTTR minimizes downtime and increases asset availability, directly contributing to higher productivity and operational efficiency. Faster repairs also lead to better asset health, extending the lifespan of critical equipment.

Maintenance Cost per Unit of Production

- Deep Dive: This KPI measures the cost of maintaining assets relative to the production output they generate. Traditionally, calculating this metric was challenging due to the lack of integrated data systems. Today, advanced technology allows for real-time tracking of maintenance costs and production levels, providing a clear view of the efficiency of maintenance activities.

- Enhancements Through Technology: Integrated systems, such as ERP (Enterprise Resource Planning) platforms combined with IoT, can track maintenance expenditures and correlate them with production data. Predictive maintenance further optimizes this KPI by reducing unnecessary maintenance tasks, ensuring that maintenance efforts are aligned with actual needs.

- Impact on Business: Lower maintenance costs per unit of production indicate more efficient use of resources, contributing to higher profit margins. This KPI also helps organizations identify and eliminate wasteful practices, leading to more sustainable operations.

Predictive Maintenance Compliance

- Deep Dive: This KPI tracks the percentage of maintenance activities performed based on predictive analytics rather than reactive or scheduled maintenance. As organizations shift towards predictive maintenance, this KPI becomes increasingly important in measuring the effectiveness of technology adoption.

- Enhancements Through Technology: Predictive maintenance tools use data from IoT sensors to predict when maintenance is needed. By monitoring asset conditions in real time, these systems can schedule maintenance only when necessary, avoiding unnecessary downtime and extending asset life.

- Impact on Business: High compliance with predictive maintenance leads to fewer unexpected breakdowns, reduced maintenance costs, and increased asset availability. This KPI also reflects the organization’s maturity in adopting advanced maintenance strategies.

Asset Downtime

- Deep Dive: Asset downtime is a critical KPI that measures the total time assets are not operational due to failures or maintenance. Traditional methods of tracking downtime were often reactive and lacked the precision needed to identify root causes. Advanced technology now allows for continuous monitoring and precise tracking of downtime.

- Enhancements Through Technology: IoT sensors and CMMS can automatically log downtime events, providing detailed reports on the duration and cause of each instance. Predictive maintenance further reduces downtime by addressing potential issues before they lead to failures.

- Impact on Business: Minimizing downtime is crucial for maintaining high levels of productivity and operational efficiency. Reduced downtime also leads to lower maintenance costs and higher overall asset availability, directly impacting the bottom line.

Return on Assets (ROA)

- Deep Dive: ROA measures the profitability generated by assets relative to their cost. This KPI is a critical indicator of how efficiently an organization is using its assets to generate profit. Traditional ROA calculations often relied on static financial data, but advanced technology allows for more dynamic and accurate assessments.

- Enhancements Through Technology: Real-time data from IoT sensors, combined with advanced analytics, provides a more accurate picture of asset performance and profitability. By continuously monitoring asset health and utilization, organizations can make informed decisions about asset deployment, maintenance, and replacement.

- Impact on Business: Higher ROA indicates that assets are being used effectively to generate profit, leading to better financial performance. This KPI also helps organizations identify underperforming assets, allowing for more strategic asset management and investment decisions.

Asset Condition Index (ACI)

- Deep Dive: ACI is a composite KPI that provides an overall assessment of asset health and condition. Traditionally, this metric was based on periodic inspections and manual assessments, which could be subjective and inconsistent. With the advent of advanced technology, ACI can now be calculated using real-time data from IoT sensors and automated inspections.

- Enhancements Through Technology: IoT devices continuously monitor critical parameters such as vibration, temperature, and operational efficiency, feeding data into algorithms that calculate a real-time Asset Condition Index. This provides a more accurate and objective assessment of asset health, allowing for timely maintenance and replacement decisions.

- Impact on Business: A high ACI indicates that assets are in good condition and likely to perform reliably, reducing the risk of unexpected failures. This KPI also helps in prioritizing maintenance activities, ensuring that resources are allocated to where they are most needed.

REQUEST A CALL BACK

Inventory Turnover Rate

- Deep Dive: Inventory Turnover Rate measures how frequently inventory is used and replaced over a specific period. In asset management, this KPI is crucial for ensuring that spare parts and consumables are managed efficiently. Traditional inventory management often led to either overstocking or stockouts, both of which are costly. Advanced technology, such as IoT and automated inventory management systems, has revolutionized this KPI.

- Enhancements Through Technology: Automated inventory management systems, integrated with IoT, can provide real-time data on inventory levels, usage patterns, and lead times. This allows for more accurate forecasting and replenishment, reducing the risk of stockouts and minimizing carrying costs.

- Impact on Business: A high Inventory Turnover Rate indicates that inventory is being managed efficiently, reducing holding costs and freeing up capital for other uses. This KPI also ensures that necessary parts are available when needed, minimizing downtime and improving asset availability.

Energy Consumption per Asset

- Deep Dive: Energy consumption is a significant cost in many industries, and this KPI measures the energy usage of individual assets. Traditionally, energy consumption was tracked at the facility level, making it difficult to identify inefficiencies at the asset level. Advanced technology now allows for precise monitoring of energy usage per asset, providing more granular insights.

- Enhancements Through Technology: IoT-enabled energy monitoring systems can track the energy consumption of each asset in real-time, identifying inefficiencies and opportunities for optimization. This data can be used to implement energy-saving measures, such as optimizing operating schedules or upgrading to more efficient equipment.

- Impact on Business: Reducing energy consumption per asset lowers operational costs and contributes to sustainability goals. This KPI also helps organizations identify energy-hungry assets, enabling targeted upgrades or replacements to improve overall energy efficiency.

Conclusion: The Future of Asset Management

As the business landscape continues to evolve, the importance of effective physical asset management cannot be overstated. The integration of advanced technologies into asset management practices is not just about improving efficiency; it’s about transforming the way organizations operate, making them more agile, resilient, and competitive in a fast-paced, ever-changing environment. By focusing on these key performance indicators and leveraging the power of advanced technology, businesses can achieve unparalleled levels of operational excellence, driving success now and in the future.

Whether it’s improving asset utilization, reducing downtime, or optimizing energy consumption, the KPIs discussed here provide a roadmap for organizations looking to enhance their physical asset management strategies. As technology continues to advance, the potential for further improvements in these areas will only grow, offering exciting opportunities for those who are ready to embrace the future of asset management.

CHECK MORE

-

Optimizing Asset Total Cost of Ownership (TCO): Best Practices and Deep Dive

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

October 10, 2024 -

Effective FM Contract Mobilization: A Comprehensive Guide to Seamless Transition and Execution

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Mastering Facilities Management: A Comprehensive Guide to Effective Management

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Turning Setbacks into Success: 5 Traits For Every Entrepreneur to Stay Strong and Focused on the Big Picture!

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 21, 2024