A Deep Dive into 9 Key Success Factors for Physical Asset ManagementTransforming Physical Asset Management

Effective management of physical assets has become a cornerstone of operational excellence and long-term sustainability. As companies strive to optimize performance and minimize costs, the integration of advanced technologies into asset management practices has emerged as a critical differentiator. Technologies such as the Internet of Things (IoT), Radio-Frequency Identification (RFID), and predictive analytics are revolutionizing the way organizations manage their physical resources, providing unprecedented levels of control, insight, and efficiency.

These innovative tools enable real-time tracking and monitoring of assets, predictive maintenance to prevent costly downtime, and comprehensive data analysis to inform strategic decision-making. By harnessing the power of these technologies, businesses can enhance asset performance, extend their lifespan, and ensure compliance with regulatory standards.

In this blog, we will explore the key success factors for physical asset management, focusing on the transformative impact of advanced technology. We will delve into best practices for leveraging these tools to streamline asset tracking, improve maintenance processes, and foster a culture of continuous improvement. Join us as we uncover how cutting-edge technology can elevate your asset management strategy and drive your organization towards greater efficiency and success.

1. Comprehensive Asset Tracking and Management

- Inventory Management Systems: Traditional inventory management systems often fall short in providing real-time visibility into asset locations, conditions, and usage. By integrating advanced technologies like RFID and IoT, organizations can achieve granular tracking of every asset. RFID tags allow for seamless identification and tracking, reducing the time and labor involved in manual checks. IoT devices further enhance this by continuously monitoring asset conditions—such as temperature, humidity, and usage patterns—enabling timely interventions to prevent asset degradation.

Case Study: A manufacturing plant implemented an IoT-based asset tracking system that reduced asset loss by 30% and improved inventory accuracy by 25%. The systemalso provided real-time alerts when assets were moved outside designated areas, enhancing security and control.

2. Preventive and Predictive Maintenance

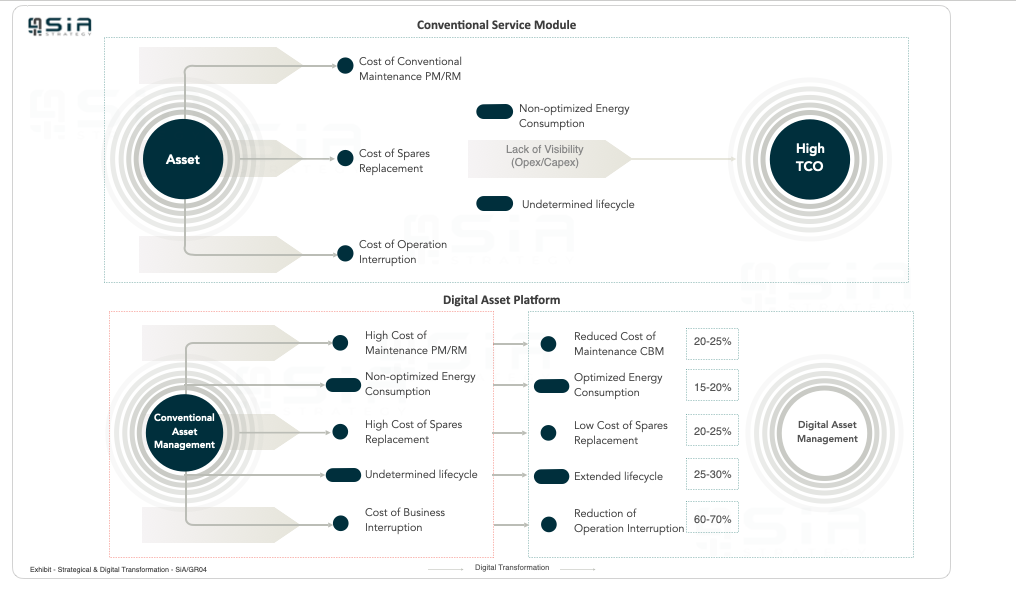

- CMMS (Computerized Maintenance Management Systems): CMMS solutions have evolved from basic scheduling tools to sophisticated platforms that integrate with IoT and AI. These systems can now predict potential failures before they occur, based on data collected from sensors attached to critical machinery. This shift from reactive to proactive maintenance drastically reduces unplanned downtime, which can be costly both in terms of time and resources.

- Predictive Analytics: Using historical data and machine learning algorithms, predictive analytics can forecast when a machine is likely to fail. This allows maintenance teams to schedule repairs during planned downtimes, thus minimizing disruptions to production. Predictive maintenance has been shown to reduce maintenance costs by up to 30% and increase equipment uptime by 20%.

- Case Study: A large energy company used predictive maintenance analytics to monitor the performance of its turbines. This approach led to a 15% reduction in maintenance costs and a 12% increase in operational efficiency.

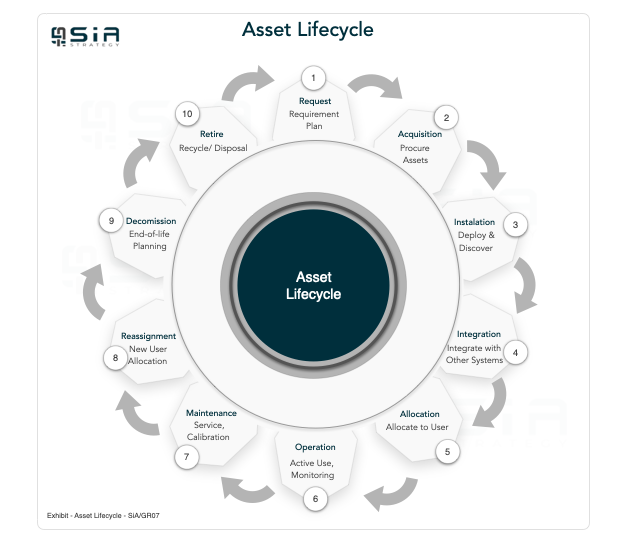

3. Lifecycle Management

- Asset Lifecycle Management (ALM): Effective asset management goes beyond just monitoring current performance—it requires a comprehensive view of the entire asset lifecycle. ALM systems track every stage of an asset’s life, from acquisition and deployment to operation, maintenance, and eventual disposal. This holistic approach ensures that assets are utilized to their fullest potential, with replacements or upgrades planned based on detailed lifecycle data.

- Depreciation Tracking: Advanced ALM systems include features for tracking depreciation, allowing companies to accurately value their assets over time. This is crucial for financial reporting and helps in making informed decisions about when to replace or retire assets.

Case Study: A healthcare provider implemented an ALM system to manage its fleet of medical equipment. The system enabled the provider to extend the life of its equipment by 20%, reducing capital expenditure and improving service delivery.

4. Data-Driven Decision Making

- Big Data Analytics: The vast amounts of data generated by modern asset management systems can be overwhelming. Big data analytics tools help organizations sift through this data to uncover valuable insights. By analyzing trends and patterns, companies can make informed decisions about asset purchases, maintenance schedules, and operational strategies.

- Dashboards and Reporting: Visualization tools like dashboards provide a clear, real-time view of asset performance. These tools allow managers to quickly identify issues, monitor KPIs, and make data-driven decisions. Customizable reports can be generated to provide detailed analysis for specific assets or operations, aiding in strategic planning and performance optimization.

Case Study: A logistics company used big data analytics to optimize its fleet management. The insights gained led to a 10% reduction in fuel costs and a 15% increase in delivery efficiency.

5. Integration with Other Systems

- ERP Integration: Integrating asset management systems with Enterprise Resource Planning (ERP) systems creates a seamless flow of information across the organization. This integration ensures that asset data is available to all relevant departments, enhancing collaboration and efficiency. For example, when a new asset is added to the system, procurement, finance, and maintenance teams can all access and update information in real time.

- IoT Platforms: Connecting physical assets to IoT platforms enables automated data collection and analysis, reducing the need for manual data entry and minimizing errors. IoT platforms can also integrate with other systems, such as CMMS and ALM, to provide a unified view of asset performance and management.

Case Study: A global manufacturing firm integrated its asset management system with its ERP and IoT platforms, resulting in a 20% reduction in operational inefficiencies and a 15% increase in asset utilization.

6. Workforce Training and Engagement

- Training Programs: Advanced technology in asset management requires a skilled workforce capable of operating and maintaining these systems. Ongoing training programs are essential to keep employees updated on the latest tools and practices. Training should cover not only technical skills but also the importance of data accuracy and compliance.

- Engagement Strategies: Engaging employees in the asset management process is crucial for success. This can be achieved through regular feedback sessions, recognition programs, and involving staff in decision-making processes. A well-engaged workforce is more likely to adhere to best practices and contribute to continuous improvement efforts.

Case Study: An automotive company implemented a comprehensive training program for its maintenance staff on using predictive analytics tools. This led to a 25% improvement in maintenance efficiency and a significant reduction in equipment downtime.

7. Regulatory Compliance and Risk Management

- Compliance Monitoring: With increasing regulatory scrutiny, ensuring that assets meet all compliance requirements is critical. Advanced asset management systems can automate compliance tracking, ensuring that all assets adhere to relevant standards and regulations. This reduces the risk of non-compliance, which can lead to costly fines and operational disruptions.

- Risk Assessment: Regular risk assessments help identify potential issues before they become critical. By integrating risk management tools with asset management systems, companies can proactively address vulnerabilities and improve overall asset reliability.

Case Study: A pharmaceutical company used an integrated compliance and asset management system to ensure all its equipment met stringent industry regulations. This approach led to a 30% reduction in compliance-related issues and improved audit outcomes.

8. Sustainability and Environmental Considerations

- Green Practices: As sustainability becomes a business imperative, integrating green practices into asset management is essential. This includes using energy-efficient equipment, recycling materials, and reducing waste. Advanced technology can help monitor and optimize these practices, contributing to a company’s overall sustainability goals.

- Environmental Monitoring: IoT sensors can monitor environmental conditions around assets, such as energy consumption, emissions, and waste production. This data can be used to identify areas for improvement and reduce the environmental impact of operations.

- Case Study: A data center implemented IoT-based environmental monitoring systems that optimized energy usage, leading to a 20% reduction in energy costs and a significant decrease in its carbon footprint.

9. Continuous Improvement and Innovation

- Feedback Loops: Establishing feedback loops is crucial for continuous improvement in asset management. Regularly reviewing performance data and gathering input from employees and stakeholders can identify areas for improvement. This iterative process ensures that asset management practices remain aligned with evolving business needs and technological advancements.

- Technology Upgrades: Staying ahead of technological trends is essential for maintaining a competitive edge. Regularly upgrading systems and incorporating new technologies, such as AI and machine learning, can further enhance asset management capabilities.

Case Study: A transportation company implemented a continuous improvement program that included regular technology upgrades and feedback from drivers and maintenance staff. This approach led to a 15% improvement in vehicle uptime and a 10% reduction in maintenance costs.

Conclusion

Integrating advanced technology into physical asset management is no longer a luxury but a necessity for organizations aiming to stay competitive in today’s fast-paced environment. By focusing on these key success factors—comprehensive asset tracking, preventive and predictive maintenance, lifecycle management, data-driven decision-making, system integration, workforce engagement, regulatory compliance, sustainability, and continuous improvement—businesses can optimize their asset management strategies. The result is improved operational efficiency, reduced costs, and enhanced long-term sustainability, ultimately driving greater business success.

REQUEST A CALL BACK

CHECK MORE

-

Optimizing Asset Total Cost of Ownership (TCO): Best Practices and Deep Dive

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

October 10, 2024 -

Effective FM Contract Mobilization: A Comprehensive Guide to Seamless Transition and Execution

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Mastering Facilities Management: A Comprehensive Guide to Effective Management

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Turning Setbacks into Success: 5 Traits For Every Entrepreneur to Stay Strong and Focused on the Big Picture!

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 21, 2024