The Power of AI and ML in Aligning Production with Sales Forecasts and Supply Chain Optimization

In today’s fast-paced and highly competitive business environment, the ability to align production schedules with sales forecasts and optimize the supply chain is a critical determinant of success. Companies that excel in these areas not only improve operational efficiency but also significantly enhance customer satisfaction and profitability. With the advent of Artificial Intelligence (AI) and Machine Learning (ML), businesses now have powerful tools at their disposal to achieve these goals with unprecedented accuracy and agility.

In this blog, we explore how AI and ML can revolutionize production planning and supply chain management, leading to better alignment with sales forecasts, reduced operational costs, and improved overall performance.

Understanding the Challenges: Why Traditional Methods Fall Short

Traditional production planning and supply chain management techniques often rely on historical data and linear forecasting models. While these methods have been effective to some extent, they have notable limitations

- Inaccurate Forecasts: Traditional methods struggle to adapt to rapid market changes, often leading to mismatches between production output and actual demand. This can result in either overproduction, leading to excess inventory, or underproduction, causing stockouts and missed sales opportunities.

- Inefficient Supply Chain Operations: Without the ability to predict and adapt to real-time changes in demand, supply chains can become inefficient, with delays, increased transportation costs, and disruptions in material availability.

- Inflexibility: Traditional methods are often rigid, unable to dynamically adjust to new data or unforeseen market shifts, leading to operational inefficiencies.

These challenges highlight the need for a more agile, data-driven approach—one that AI and ML are uniquely positioned to provide.

The AI and ML Advantage: How Technology Transforms Production and Supply Chain Management

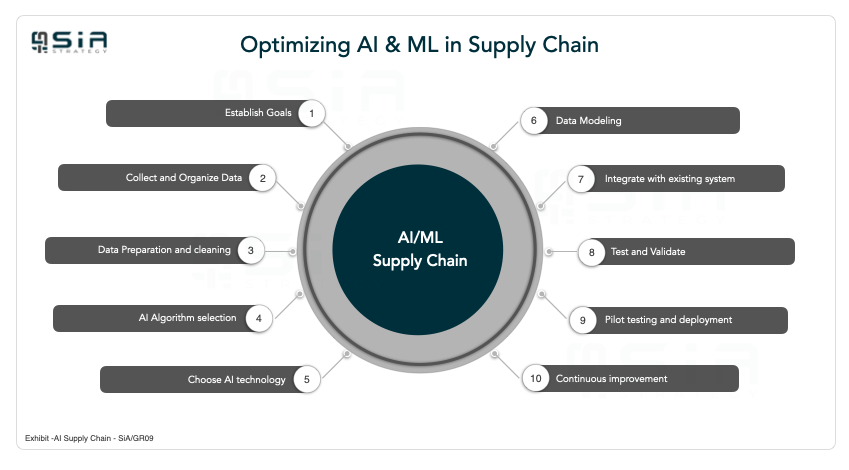

AI and ML offer transformative capabilities that address the limitations of traditional methods. Here’s how these technologies can be leveraged:

1. Advanced Forecasting Models

- Data Integration:AI and ML models can analyze vast amounts of historical sales data, market trends, and external factors such as economic indicators and seasonality. By integrating data from multiple sources, these models can predict future demand with much greater accuracy.

- Real-Time Adjustments:Unlike static forecasting methods, AI-driven models continuously learn from new data, allowing them to adapt to changing market conditions in real-time. This ensures that production schedules are always aligned with the most current sales forecasts.

2. Optimized Production Planning

- AI-Driven Scheduling:AI can optimize production schedules by aligning them with refined sales forecasts. This reduces the risk of overproduction or underproduction, ensuring that output closely matches demand.

- Predictive Maintenance:AI can also predict when machinery is likely to fail, enabling proactive maintenance and reducing downtime. This keeps production running smoothly and efficiently

3. Supply Chain Optimization

- Demand-Driven Supply Chains:ML algorithms can analyze demand forecasts and optimize supply chain operations accordingly. This includes everything from procurement and inventory management to distribution and logistics, ensuring that materials are available when needed and products are delivered on time.

- Resilience and Agility:AI enhances supply chain resilience by identifying potential disruptions and allowing for rapid adjustments. This reduces the impact of unforeseen events and helps maintain continuity in supply chain operations.

4. Continuous Improvement

- Feedback Loops:AI and ML enable continuous improvement by establishing feedback loops between sales, production, and supply chain teams. This allows for ongoing refinement of forecasting models and planning processes, ensuring that the system becomes increasingly accurate and efficient over time.

Real-World Impact: Case Study Insights

To illustrate the real-world impact of AI and ML, consider the case of Precision Manufacturing Co., a company that successfully implemented these technologies to align its production with sales forecasts and optimize its supply chain.

Opportunity: Precision Manufacturing Co. faced significant challenges in aligning production schedules with fluctuating sales forecasts and managing its supply chain efficiently. The company experienced frequent mismatches between production and demand, leading to excess inventory, stockouts, and increased operational costs.

Solution: The company implemented AI-driven forecasting models to analyze historical sales data, market trends, and external factors. These models provided more accurate demand predictions, allowing for better alignment of production schedules. Additionally, AI was used to optimize supply chain operations, from procurement and inventory management to distribution logistics.

Impact:

- Improved Forecast Accuracy: The company saw a 30% improvement in forecast accuracy, leading to more efficient inventory management and reduced operational costs.

- Optimized Production Planning: Production lead times were reduced by 20%, and overall operational costs decreased by 18%.

- Streamlined Supply Chain: Supply chain costs were reduced by 25%, with improved material availability and enhanced delivery performance.

- Increased Customer Satisfaction: The alignment of production with demand and optimized supply chain operations resulted in higher customer satisfaction and loyalty.

The Future of Production and Supply Chain Management with AI and ML

As AI and ML continue to evolve, their applications in production planning and supply chain management will only expand. Businesses that embrace these technologies will be better positioned to respond to market changes, optimize their operations, and achieve sustainable growth.

Future advancements may include:

- Predictive Analytics for Market Trends: AI could further refine its ability to predict market trends, allowing businesses to anticipate shifts in demand even before they occur.

- End-to-End Supply Chain Visibility: AI-powered platforms could provide complete visibility across the entire supply chain, enabling even more precise coordination between suppliers, manufacturers, and distributors.

- Autonomous Supply Chains: With AI, the future may see more autonomous supply chains where AI systems make decisions in real-time, optimizing every aspect from production to delivery without human intervention.

Conclusion

AI and ML are no longer just buzzwords—they are powerful tools that can drive significant improvements in production planning and supply chain management. By leveraging these technologies, businesses can achieve better alignment with sales forecasts, optimize their supply chain operations, reduce costs, and enhance customer satisfaction.

For companies looking to stay competitive in an increasingly dynamic market, the integration of AI and ML into production and supply chain processes is not just an option—it’s a necessity. Embrace these technologies today, and unlock the potential for smarter, more efficient operations that lead to lasting success.

REQUEST A CALL BACK

CHECK MORE

-

Optimizing Asset Total Cost of Ownership (TCO): Best Practices and Deep Dive

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

October 10, 2024 -

Effective FM Contract Mobilization: A Comprehensive Guide to Seamless Transition and Execution

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Mastering Facilities Management: A Comprehensive Guide to Effective Management

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 28, 2024 -

Turning Setbacks into Success: 5 Traits For Every Entrepreneur to Stay Strong and Focused on the Big Picture!

Supported by a robust sales force and tight cost controls, Pharm Ltd. experienced sustained double-digit growth over a number of years, only to find that their supply chain struggled to keep pace.

September 21, 2024